The ENLIGHTENED project addresses these challenges head-on. With the ultimate goal of combining photovoltaic cells with flexible circuit boards, energy storage, and electronic components in an affordable, automated, and flexible manner, ENLIGHTENED is bringing together leading researchers, manufacturers of printed and non-printed electronics, service providers, and end customers. This collaboration aims to establish the standard for flexible hybrid electronics assembly of light-powered electronics while positioning ENLIGHTENED as a thought leader in the next generation of sustainable electronics manufacturing.

At FLEXOO, we're contributing to this transformation by developing and rigorously testing copper-based conductive inks that promise to reduce both environmental impact and production costs while maintaining the performance standards that light-powered, flexible electronics demand.

Silver-based conductive inks have long been the industry standard, offering excellent conductivity and reliability. However, silver's price volatility - recently reaching $32 per ounce - creates significant economic uncertainty for manufacturers. Beyond cost considerations, the environmental footprint of precious metal extraction and processing conflicts with the sustainability goals central to ENLIGHTENED's vision.

FLEXOO's copper ink innovation directly supports the ENLIGHTENED mission by delivering reliable conductivity without the economic and environmental drawbacks of precious metals. Copper offers critical advantages for light-powered electronics:

The games have begun. May the best ink win.

Seven copper ink formulations entered our testing arena. Only the strongest will advance to roll-to-roll production in the ENLIGHTENED project. This isn't about incremental improvements - it's about identifying production-ready solutions that can establish the standard for flexible hybrid electronics.

We evaluate achievable line widths and spacings through visual inspection and resistance measurements between adjacent lines. For photovoltaic integration with flexible circuit boards, precision matters. Every formulation must demonstrate the capability to create fine-pitch circuitry essential for compact, light-powered electronics.

Layer thickness, roughness, and waviness analysis ensures consistent print quality across large-scale automated production. Conductivity measurements verify that each formulation meets the performance targets required for efficient energy transmission from photovoltaic cells to electronic components.

Flexibility testing ensures compatibility with bendable substrates - a core requirement for ENLIGHTENED's flexible hybrid electronics. Cross-hatch and pull-off tests evaluate adhesion, while scratch resistance assessment verifies real-world durability. No shortcuts. No second chances.

Each ink must prove its worth across long-term stability testing. Climate chambers simulate years of operation under varying environmental conditions, providing crucial reliability data for light-powered electronics that must perform consistently throughout their lifecycle.

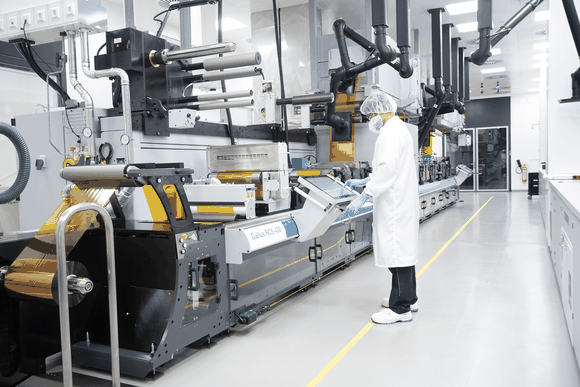

Beyond basic ink performance, we're developing the complete printing parameter set necessary for automated roll-to-roll manufacturing: printing speed, pressure, temperature, and curing conditions optimized for the flexible, hybrid assembly approach central to ENLIGHTENED's vision.

Early results demonstrate promising performance across all critical metrics. The copper ink formulations show competitive conductivity levels while offering the cost stability and environmental benefits that make affordable, light-powered electronics achievable at scale.

FLEXOO's systematic material selection and development process ensures only production-ready solutions advance toward the ENLIGHTENED goal: establishing the standard for flexible hybrid electronics assembly that combines photovoltaic power with functional circuit boards and components in a unified, automated production process.

The ENLIGHTENED project represents more than incremental innovation - it's establishing a new paradigm for sustainable electronics manufacturing. FLEXOO's copper ink development directly enables the project's vision by providing the material foundation for affordable, automated production of flexible, light-powered electronics.

Our rigorous testing process ensures that the transition from precious metal-based inks to copper alternatives doesn't compromise performance or reliability. Instead, it opens new possibilities for cost-effective, environmentally conscious electronics that integrate energy generation, storage, and functionality in flexible form factors.

The combination of economic stability, environmental benefits, and proven performance capability positions copper-based solutions as a cornerstone technology for flexible hybrid electronics. As we continue testing and refinement, copper inks are proving their capability to support ENLIGHTENED's ambitious goal: making light-powered, flexible electronics the standard, not the exception.

The future of electronics manufacturing lies in innovations that balance performance, cost, and environmental responsibility. Through the ENLIGHTENED project, we're not just developing new materials - we're helping to define the standards that will guide the industry toward truly sustainable, energy-autonomous electronics.